Technology

Location:Home > Technology

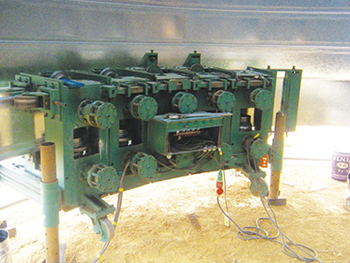

The main equipments for slio making machine:

Decoiling machine, bending machine, forming machine,frames&supports, electrical control.The main current equipments are mainly SM30 and SM40 type two specifications:SM30 suitable for silo diameter range 3 ~ 10 meters; SM40 suitable for silo diameter range 6 ~ 25 meters.

English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Russian

Russian